Qylite® 200 & 400

-

Lightweight, High Performance Foam for Sound Absorbtion

FXI acoustical solutions are engineered to perform multiple functions

including sound absorption and vibration damping. FXI low-density foams

are ideal for sound absorption while higher-density or lower permeability

foams work well for damping. Complementing their acoustic capabilities,

all FXI foams are moldable and meet various fire and performance

requirements. Additionally, these acoustic technologies can withstand

varying operating temperatures and offer insulation performance for

different industry applications. FXI acoustical solutions provide efficiency,

reliability, and predictability in high-stress environments and applications

over time, while simplifying handling, manufacturing and assembly, to

reduce overall costs for sound and vibration reduction solutions.

FXI acoustical solutions are engineered to perform multiple functions

including sound absorption and vibration damping. FXI low-density foams

are ideal for sound absorption while higher-density or lower permeability

foams work well for damping. Complementing their acoustic capabilities,

all FXI foams are moldable and meet various fire and performance

requirements. Additionally, these acoustic technologies can withstand

varying operating temperatures and offer insulation performance for

different industry applications. FXI acoustical solutions provide efficiency,

reliability, and predictability in high-stress environments and applications

over time, while simplifying handling, manufacturing and assembly, to

reduce overall costs for sound and vibration reduction solutions.

Overview

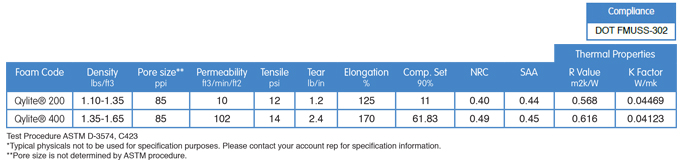

Qylite® 200 and 400 are Department of Transportation FMVSS-302 certified, and formulated with low-density ether foam technology having unique lightweight cellular structures that enhance sound absorbing performance with some damping characteristics. Qylite® 200 and 400 perform well in harsh environments and facilitate many final form processing methods like compression molding where aesthetics and engineered performance need to be balanced. These foams have excellent high and low temperatures stability with attractive heat-aging, wear, and abrasion properties.

Benefits

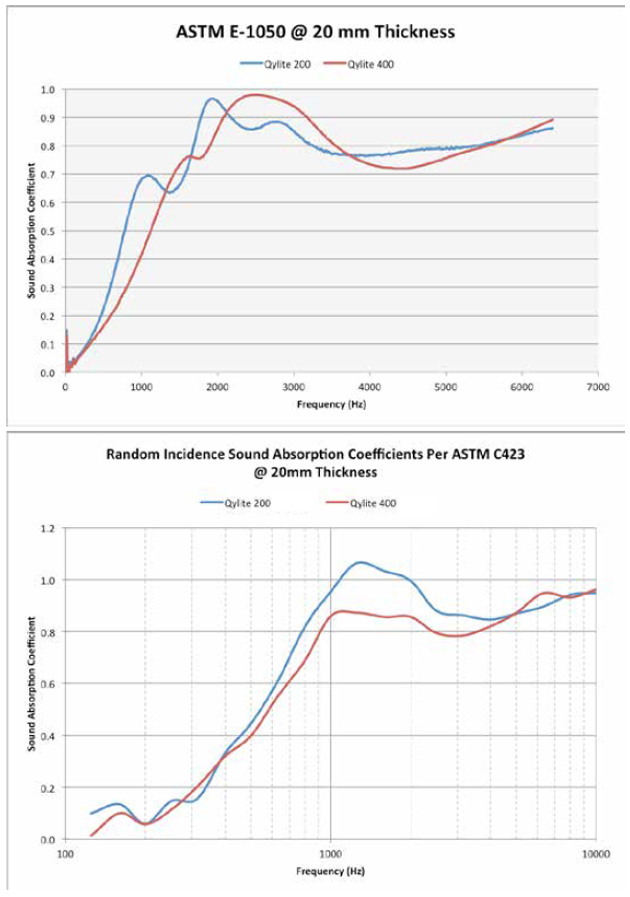

• Predictable sound absorption in a broad frequency range

• Good sound absorption across lower frequencies from 100 Hz–700 Hz

• Excellent sound absorption across frequencies from 700 Hz–5000 Hz

• Lightweight and capable of delivering sound absorbtion in tough environments

• Long service life due to the ability to maintain structure and acoustic properties despite heat-aging, wear, and abrasion

• Manufacturing friendly with the ability to hold loft and form which limits the need for additional steps in processing and assembly

• Increased design flexibility due to the ability to fabricate to achieve form and fit. i.e. compressed molding, die cut, water, jet cut, etc.